Pocket Knife (Pocket Knife) is probably the most widely used and popular knife in the world. According to research markers, this knife has been around for over 1600 years. However, while the blade, handling materials, design, branding, ergonomics and other attributes of a pocket folding knife are important to many enthusiasts, the real heart of a pocket folding knife is the locking mechanism. Today Cold Jun will introduce the types of knife locks on pocket folding knives.

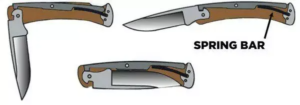

Back lock (Lockback)

Lockback (also known as rear lock, ridge lock or center lock) is derived from non-locking joints. The lock lever is fixed to the blade with the pivot point in the middle and a bent spring behind the handle to provide upward pressure behind the pivot point, and the lock lever in front when pressed. In the latched position, the locking lever sits on a ramp at the bottom of the shank foot which provides a stop for opening.

When the blade is opened, the forward portion of the locking lever, with its square protrusion, falls into a matching square cutout at the top of the blade shank foot, locking it into place. The cutout in the shank foot matches the shape of the locking bar, meaning that the bar must be lifted out of the notch in order to release the blade. Therefore, the spring-loaded lever remains latched until the lever is held against the pressure of the spring-loaded open blade from behind the pivot point.

▲Triple lock (back lock variant)

▲Electric lock (back-lock variant)

Advantages: The backlock design is dexterous, as its actuation is done along the spine and does not cross each other, and the lock lever is also usually much thicker than a typical liner lock, the same width as the blade itself.

Disadvantages: After many repetitions of opening and closing, it can create play, resulting in abnormal opening and closing; and requires special care when used with one hand.

Professional advice: Take care to periodically clean the lint left on the square cut of the blade shank with a pocket screwdriver, compressed air or toothbrush to prevent locking difficulties.

Liner Lock

The liner lock (or translated as straight lock) is probably the most common form of lock for modern folding knives – easy to use and easy to assemble. The basic design uses the blade’s liner, cut and bent to create a spring effect that engages the back of the blade when it is opened. Modern liner locks were introduced by custom knifemaker Michael Walker with two important upgrades: the addition of a retaining pin and a stop detent.

Pros: Easy to use and inexpensive.

Disadvantages: The liner is thin and cannot carry heavy striking operations.

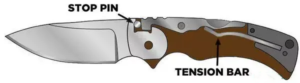

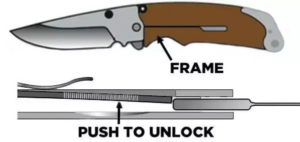

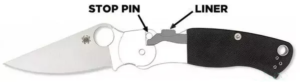

Frame Lock (Frame Lock)

The Frame Lock is the most common form of folding knife lock after the Pad Lock. It was first used in 1990 and has since undergone a series of revisions. The concept is similar to the liner lock, but stronger and simpler. It is relatively thick on the side with the lock, forming the entire handle. A cutout in the axis of the spine relieves internal pressure. When the blade opens, the lock lever springs inward against the back of the blade to lock it in place, and the stop ball engages the hole in the bottom of the blade to keep it closed and provide tension for the tight opening. A stop pin mounted above and in front of the pivot establishes the final position of the blade when opened and also helps to eliminate wear on the locking lever.

▲FRAME LOCKS

Pros: Very strong, simple construction, few parts.

Cons: Titanium is prone to wear and tear, and opening and closing is dependent on pivot tension.

Compression Lock (Compression Lock)

The Compression Lock is considered an improved inverted liner lock, which was developed and patented by Spyderco. The blade pops out along the spine of the blade and the hand doesn’t act directly on the blade when retracted.

Pros: Stronger than liner locks, easy to use.

Disadvantages: Requires precise machining.

Pro tip: When adjusting pivot tension, also tighten both pivot pins and then loosen the stop pin slightly (about a quarter) so the blade will open and close more smoothly.

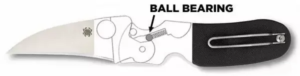

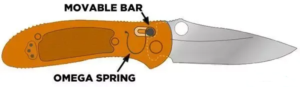

Axis Locks and Derivatives

The Axis Lock is an interesting lock: the steel bar passes through slots in the handle and liner, two “Ω” shaped springs provide equal tension on both sides of the bar, and the stop pin locates the blade for increased reliability.

▲Ball Bearing Lock

▲Ball Bearing Lock Ball bearing lock (simplified version of shaft lock)

▲Arc-Lock (shaft lock variant)

Advantages: Easy to close, high strength.

Disadvantages: Spring is easy to break, easy to accumulate dust.

Pro tip: Pay attention to the spring of the locking mechanism on the drive shaft or similar device; if the lock begins to engage or disengage unevenly, it may be a sign of impending spring failure.

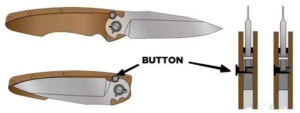

Button Locks (Button Locks)

Button locks (or plunger locks) are the method of opening and closing an automatic knife. When the blade is fully open, the plunger (the round internal part of the button lock) engages the cutout in the foot of the blade handle.

Advantages: Very strong locking force.

Disadvantages: Difficult and expensive to manufacture.

Collar Lock

Collar lock is undoubtedly the most iconic feature of French folding knives and is simple to operate: just twist the blade into the slot and you’re done.

Advantages: low cost, easy to operate

Disadvantages: Over time, the collar or ring may harden, thus preventing smooth operation of the folding blade.

Pro tip: After long term use, the ring needs maintenance. If it turns too loose, tighten it with pliers. If it is too tight, use a pair of pliers to pry it open a bit and add some lubricant.